Wire ropes endure constant stress, tension, bending, and exposure to harsh conditions. Over time, this leads to wear and tear that can compromise safety and performance. Ignoring worn wire ropes increases the risk of lifting failures, equipment damage, and workplace accidents.

When to replace a wire rope

Watch for the following warning signs and if you notice any of these, replace the rope immediately to avoid operational hazards:

- Frayed or broken strands

- Reduced rope diameter

- Kinks, twists, or birdcaging

- Corrosion or rust

- Uneven wear or crushing

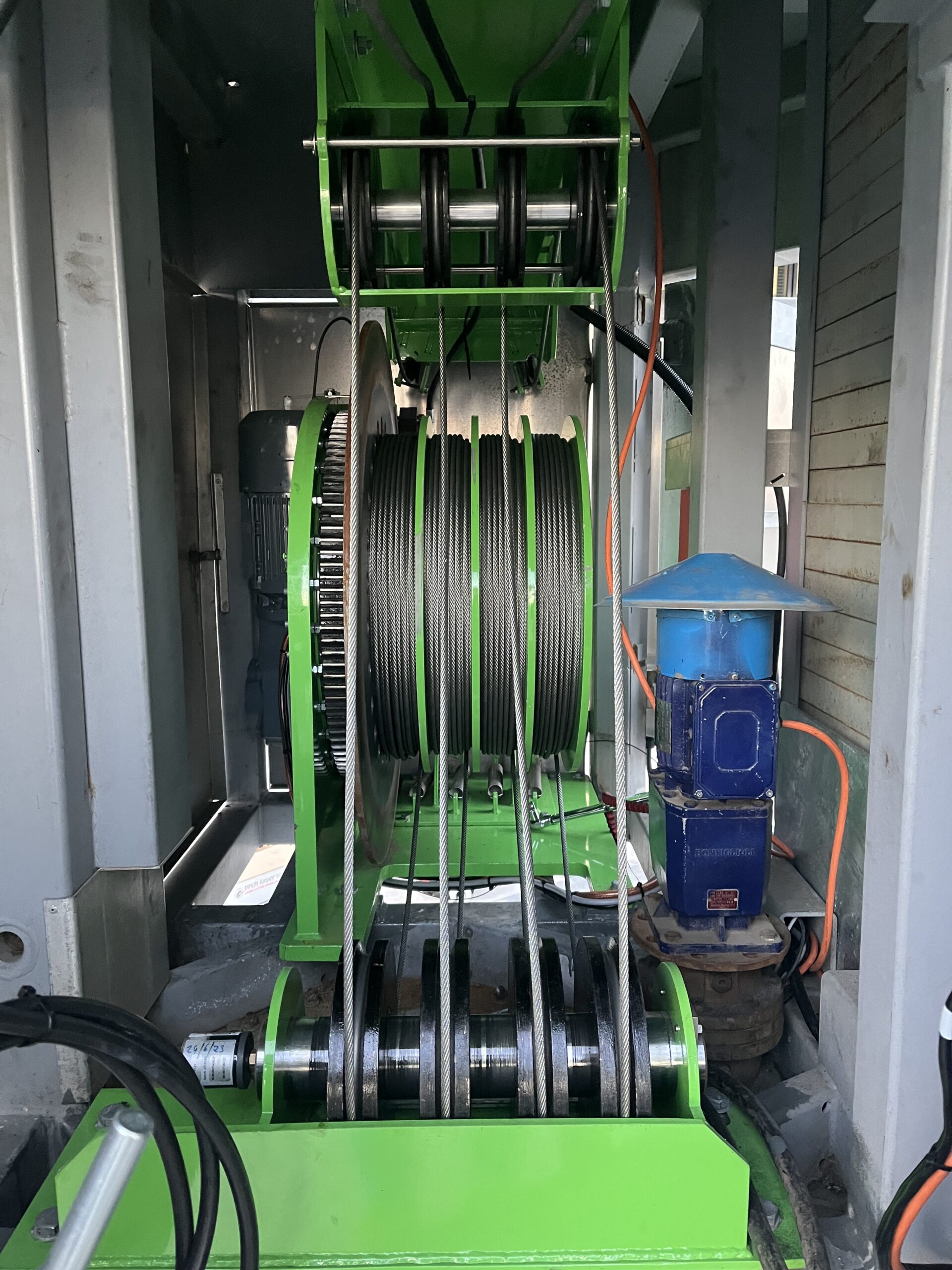

Our replacement process

We adhere to a certified, structured process that ensures each rope replacement is performed accurately, with minimal downtime and maximum operational safety.

- Inspection & assessment

Visual and mechanical checks to identify wear, damage, and verify specifications. - Wire rope selection

High-performance, load-rated ropes tailored to your access system. - Safe removal & installation

Our team removes the old rope and installs the new one with proper tensioning and alignment. - Testing & adjustment

We verify tension, alignment, and functionality to ensure safe operation. - Final safety check & certification

Each replacement is completed with a compliance inspection and ISO-standard certification.

BMU maintenance recommendations

- Replace copper core lifting ropes every 4-5 years, unless your manual states otherwise.

- Replace non-copper core ropes every 10 years, unless specified otherwise.

- Service providers must maintain records of rope replacements, inspections, and due dates including rope construction certificates.

Schedule your wire rope replacement

Check your records to guarantee your BMU is compliant with Australian Standards, your Manufacturers specifications and WorkSafe regulations.

Get in touch with Vertimax Australia team for expert replacement services. We’ll keep your access equipment safe, compliant, and operating at peak performance.

Sorry, the comment form is closed at this time.